Off the keyboard of Albert Bates

Off the keyboard of Albert Bates

Follow us on Twitter @doomstead666

Friend us on Facebook

Published on Peak Surfer on June18 & 25, 2017

Discuss this article at the Environment Table inside the Diner

Ground Up

Over and over again during the workshop we heard that “farmers are conservative,” “nobody is going to pay for something that takes years to show its worth,” and “unless you spend the time to make it, you won’t even be able to get any.” This is where biochar is today in agriculture. Its a better mousetrap in the midst of a huge rodent epidemic and still, most people can’t even buy any.

Because we are busy with the workshop we can’t easy cut out the time to pen a blog, so we taped (feebly, using a collection of devices such as phones and voice recorders) a segment of one talk we gave during the week. Enjoy.

—————————

Concrete Solutions

We screen grabbed these images off earth.nullschool.net when we were looking at Tropical Storm Cindy on June 19. The top image shows Earth’s oceans. Red is hotter than normal. Blue is colder than normal. The Polar seas are colder than usual because of all the fresh ice water from melting glaciers and ice shelves.

We screen grabbed these images off earth.nullschool.net when we were looking at Tropical Storm Cindy on June 19. The top image shows Earth’s oceans. Red is hotter than normal. Blue is colder than normal. The Polar seas are colder than usual because of all the fresh ice water from melting glaciers and ice shelves.

Last week I visited a small slice of heaven; The Farm in Summertown, TN. The Farm is [one of] the oldest intentional communit[ies] in the country and has been home to Albert Bates, author of The Biochar Solution amongst other books, for decades.

Biochar experimentation at The Farm spans the gamut from soil amendment to building material to humanure additive which then moves over to worm bins for some final processing. Just walking around the various natural buildings and permaculture filled ambiance was enough to inspire, but actually getting my hands dirty making biochar plasters, cement mixes, bricks, filtration devices with other like-minded folks was soul boosting.

We visited a nearby farmer that feeds his livestock (pigs, goats, poultry) an earthy blend of biochar mixed with lightly fermented whey and grains which they gobbled up greedily. We used rather grand outhouses that mitigated odors and reduced nutrient leaching with a blend of biochar and sawdust. And we shared stories of our mutual journeys, lessons learned and best practices along the biochar continuum.

What I really enjoyed about this experience, especially compared to attending biochar and other related conferences which tend to pack an enormous amount of information into back-to-back 15–20 minute sessions all day long for 3 days, was the more relaxed pace, the ability to get to know everyone there and hear about their own particular biochar experiences. The other fun part was leveraging everyone’s tools and backgrounds to take certain ideas further — such as the chardboard paper which I wrote about nearly 3 years ago. Albert had a contraption that was able to measure the electromagnetic shielding of the chardboard which was pretty substantial, roughly 90% reduction!

For those of you that have the time and desire to experience truly sustainable living, I highly recommend a visit to The Farm. Staying in the Fairy House, a cozy earthbag building with a living roof provides the quietest sleep you could ever dream of….

Cementing History

|

| Pantheon Oculus, Rome (126 CE) |

Quicklime (calcium oxide) is a white, caustic, alkaline, crystalline solid at room temperature, but feeling an urge to go back to rock, it will draw CO2 from the air unless slaked with water. Slaked lime is what the Romans and Chinese used for mortars and plasters. It is what Michelangelo in 1511 spread across the ceiling of the Sistine Chapel and painted the image of God into. In the 1820s scientists learned that when heated to >4,000°F (2,200°C) it emits an intense glow. That feature was used broadly in theater productions before electric lighting — limelight.

Quicklime (calcium oxide) is a white, caustic, alkaline, crystalline solid at room temperature, but feeling an urge to go back to rock, it will draw CO2 from the air unless slaked with water. Slaked lime is what the Romans and Chinese used for mortars and plasters. It is what Michelangelo in 1511 spread across the ceiling of the Sistine Chapel and painted the image of God into. In the 1820s scientists learned that when heated to >4,000°F (2,200°C) it emits an intense glow. That feature was used broadly in theater productions before electric lighting — limelight.

Run the Research

• All biochar admixtures had less weight loss due to moisture evaporation. Mortar mixes with char have better water retention. This may lead to improved strength. “In this way, biochar seems to play a role as a self-curing agent.”

• The workability of mortar decreases as the percentage of biochar increases.

• 5–10% biochar replacement is similar to 20% replacement with fly ash (the toxic residue of cement making and other industries).

• Up to 5% biochar shows an increase in compression strength.

• All char additives outperformed control bending strength, compression & fracture energy.

• Coffee powder did better on compression tests.

• Hazelnut shells did better on flexural (MOR) and fracture energy tests.

• Hazelnut shells’ irregular morphology creates “perfect bond with surrounding matrix.”

• Coffee powder has higher silicates which could work as an accelerator helping to speed up the hydration process. It stabilized at 7 days.

A study by Khushnood et al, Carbonized nano/microparticles for enhanced mechanical properties & electromagnetic interference shielding of cementitious materials (2016) tested mechanical & shielding properties of cement using peanut shells and hazelnut shells at 6 different concentrations.

A study by Khushnood et al, Carbonized nano/microparticles for enhanced mechanical properties & electromagnetic interference shielding of cementitious materials (2016) tested mechanical & shielding properties of cement using peanut shells and hazelnut shells at 6 different concentrations.

• All char additives outperformed flexural strength of control (2.96 MOR).

• Hazelnut shells optimized at .25% (5.44 MOR).

• Peanut shells optimized at .25% (5.43 MOR).

• Fine aggregates increased fracture toughness.

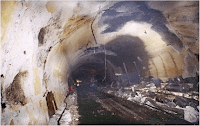

Hans-Peter Schmidt points to concrete fire resistance as more important than most people realize. In the 1999 tragedy on the autobahn through Mont Blanc, 39 people died when a Belgian transport truck carrying flour and margarine caught fire in the tunnel. The fire burned for 53 hours and reached temperatures of 1,000 °C (1,830 °F), mainly because of the margarine. While it is unlikely biochar in tunnel cements or plasters could have filtered air quickly enough to save the lives of those who suffocated from the toxic smoke, we can at least say that the repairs to the tunnel afterwards would have been easier had fire not damaged the concrete of the tunnel.

Hans-Peter Schmidt points to concrete fire resistance as more important than most people realize. In the 1999 tragedy on the autobahn through Mont Blanc, 39 people died when a Belgian transport truck carrying flour and margarine caught fire in the tunnel. The fire burned for 53 hours and reached temperatures of 1,000 °C (1,830 °F), mainly because of the margarine. While it is unlikely biochar in tunnel cements or plasters could have filtered air quickly enough to save the lives of those who suffocated from the toxic smoke, we can at least say that the repairs to the tunnel afterwards would have been easier had fire not damaged the concrete of the tunnel.

If just one percent of the sand going into the 25 billion tons of new concrete each year were replaced with biochar, 250 million tons of biochar would be sequestered. With a carbon content of 82–98 percent, that biochar is the CO2 equivalent of 738- 882 million tons per year (205–245 MtC). At present rates of emissions, we’d need to sequester 5.6 billion tons of carbon (GtC) per year just to get to carbon neutrality, 25 times more than this example. Alternatively, the biochar industry could raise its ambition and replace 25 percent of construction sand worldwide with char-crete.

If just one percent of the sand going into the 25 billion tons of new concrete each year were replaced with biochar, 250 million tons of biochar would be sequestered. With a carbon content of 82–98 percent, that biochar is the CO2 equivalent of 738- 882 million tons per year (205–245 MtC). At present rates of emissions, we’d need to sequester 5.6 billion tons of carbon (GtC) per year just to get to carbon neutrality, 25 times more than this example. Alternatively, the biochar industry could raise its ambition and replace 25 percent of construction sand worldwide with char-crete.

Biocomposites

• All biochar rates increased flexural strength by 20% or more

• Tensile strength was highest with 5% biochar

• Tensile elasticity was highest with 25% and 40% biochar

• Water absorption and swell decreased

• Biochar additions showed improved thermal properties.

All this academic research is good, but it hardly matters until it gets out of the classroom and laboratory. This is why Schmidt was in Nepal making kilns and showing biochars properties to the homeless after the earthquake in April, 2015, and why Draper is working with engineering students from RIT to design biochar concrete roof tiles in Nicaragua.

All this academic research is good, but it hardly matters until it gets out of the classroom and laboratory. This is why Schmidt was in Nepal making kilns and showing biochars properties to the homeless after the earthquake in April, 2015, and why Draper is working with engineering students from RIT to design biochar concrete roof tiles in Nicaragua.

We made chardobe brick and compressed CINVA ram brick. We made grout for a tile bench. These exercises were a tiny drop in the ocean of what is required to remove carbon from the atmosphere, but they showed the potential.

We made chardobe brick and compressed CINVA ram brick. We made grout for a tile bench. These exercises were a tiny drop in the ocean of what is required to remove carbon from the atmosphere, but they showed the potential.

|

|

|

Biocomposite “ore” from recycled polystyrene

|

|

|

Polystyrene waste at a Japanese fish market, by beth

|